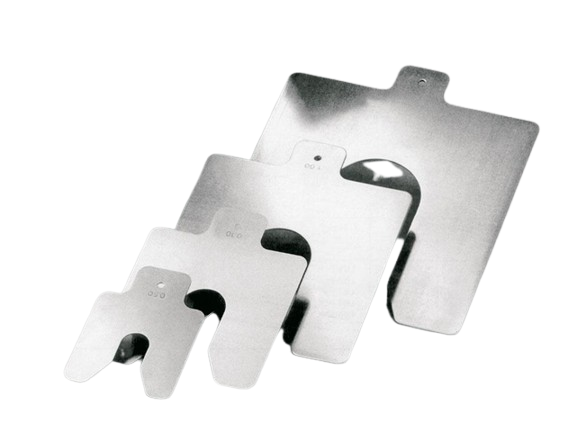

SHIMS FOR PUMP ALIGNMENT

Pump alignment shims are thin, precision-made spacers used to adjust the alignment of a pump and its driver (such as an electric motor to ensure proper alignment and optimal performance).

Installation:

- Measure the existing gap between the pump and driver.

- Select the correct shim thickness.

- Place the shim between the pump and driver.

- Recheck alignment using specialized tools (e.g., dial indicators).

Purpose:

- Reduce vibration: Misalignment can cause vibration, leading to noise, wear, and premature failure.

- Increase efficiency: Proper alignment ensures optimal power transmission and reduces energy losses.

- Extend lifespan: Correct alignment helps prevent wear on seals, bearings, and other components.

Types of shims:

- High strength-to-weight ratio and corrosion resistance.

- Plastic shims: Non-metallic, corrosion-resistant options.

- Adjustable shims: Allow for fine-tuning of alignment.

- Pre-cut shims: Available in standard sizes or custom-made.

Best practices:

- Consult manufacturer guidelines.

- Use precision measuring tools.

- Check alignment regularly.

- Replace worn-out shims.