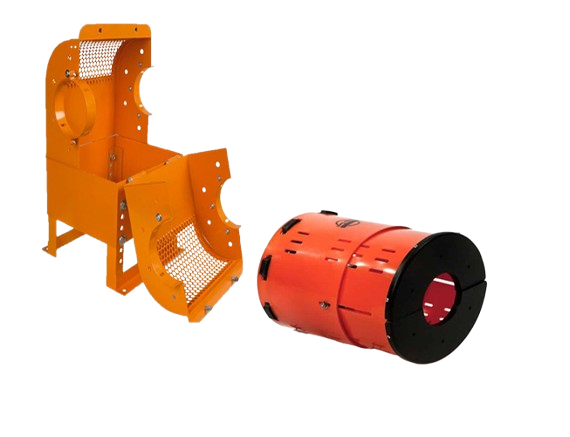

COUPLING GUARD

360-Degree Coupling Guard. A 360-degree coupling guard provides complete protection around the coupling, ensuring safety and preventing accidental contact with moving parts.

360-Degree Coupling Guard Applications:

- Pump and Motor Combinations: Protects coupling and surrounding equipment.

- Industrial Facilities: Enhances safety in industrial settings.

- Chemical Plants: Protects against chemical exposure and rotating equipment.

- Water Treatment: Safeguards against water and rotating equipment.

- Food Processing: Prevents contamination and ensures safety.

Pump and Motor Coupling Applications:

- Centrifugal Pumps: Connecting centrifugal pumps to motors.

- Positive Displacement Pumps: Connecting positive displacement pumps to motors.

- Submersible Pumps: Connecting submersible pumps to motors.

- Chemical Pumps: Connecting chemical pumps to motors.

- Wastewater Pumps: Connecting wastewater pumps to motors.

Key Features:

- Full Enclosure: 360-degree coverage around the coupling.

- Durable Material: Constructed from heavy-duty materials (e.g., steel, aluminum).

- Easy Installation: Simplified setup and attachment to pump and motor.

- Adjustable: Accommodates various coupling sizes and configurations.

- Ventilation: Allows for airflow and heat dissipation.

Benefits:

- Enhanced Safety: Protects personnel from rotating equipment and moving parts.

- Reduced Risk: Minimizes risk of accidents and injuries.

- Increased Reliability: Prevents damage to coupling and surrounding equipment.

- Easy Maintenance: Simplified maintenance and repair process.

- Compliance: Meets safety standards and regulations.

Materials of Construction:

- Steel: Durable, heavy-duty construction.

- Aluminum: Lightweight, corrosion resistant option.

- Plastic: Impact-resistant, corrosion resistant option