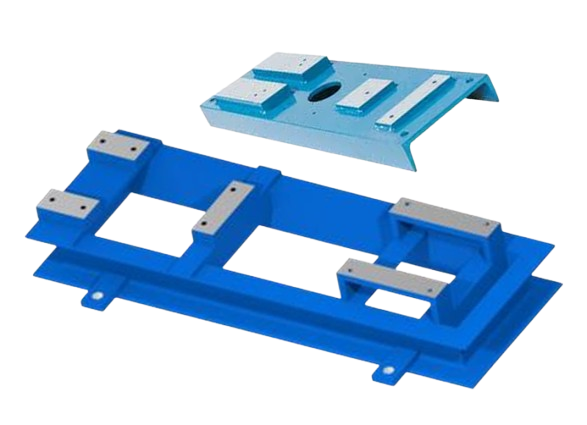

BASEPLATE MOUNTING SYSTEM

Compatibility:

- ANSI/ASME Pumps: Compatible with industry-standard pumps.

- ISO-2858 / 5199 - : Compatible with industry-standard pumps.

- IEC/ISO/NEMA Motors: Suitable for international motor standards.

Dimensions and Specifications:

- Varies depending on specific baseplate model and configuration. Consult TranspumpServ Pumps' documentationor contact their support team for detailed information.

Certifications and Compliance:

- ANSI B73.1M

- CE Marking (for EU compliance).

Key Features:

- Pre-drilled holes: Simplified installation and alignment.

- Adjustable motor mounts: Flexible motor positioning.

- Vibration damping: Minimizes vibration transmission.

- Corrosion-resistant coatings: Enhanced durability.

- Integrated drip pan: Containment of potential leaks.

Benefits:

- Easy Installation: Streamlined setup and alignment process.

- Reduced Maintenance: Simplified access, minimized downtime.

- Increased Stability: Rigid design ensures minimal vibration.

- Improved Safety: Containment of potential leaks, reduced risk.

- Customization: Meets specific plant requirements and configurations.

Materials of Construction:

- Steel: Durable, heavy-duty construction.

- Stainless Steel: Corrosion-resistant, suitable for harsh environments.

- Aluminium: Lightweight, corrosion-resistant option.

- Coatings: Epoxy, ceramic, or specialized coatings for added protection.

TranspumpServ Pumps' Baseplate Mounting Systems:

- Standard Baseplate: Durable, compact design for general applications.

- Adjustable Baseplate: Accommodates varying pump and motor configurations.

- Slide Rail Baseplate: Easy pump and motor alignment, smooth adjustment.

- Fixed Baseplate: Rigid design for high-vibration or high-load applications.

- Custom Baseplate: Tailored to meet specific plant requirements.