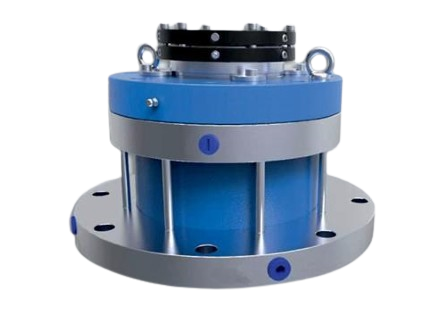

TRANS- GRB- Grommet Reverse Balance Seal

KEY FEATURES:

- Agitator Mechanical seals are designed for handling severe services including products emitting toxic vapors during reaction process

- Agitator Mechanical seal Design incorporates bearing located very close to the seal. This is the standard feature effectively arrests the shaft whip for smooth and trouble free operation enabling enhanced seal life. The cooling jacket, also a standard feature, helps to maintain cool environment around seal. Large clearance, between rotating shaft/sleeve and mating ring permits higher deflection of the shaft, invariably with top Entry Agitators..

Typical Applications:

- General chemicals and its vapour, Food products, Pharmaceuticals product, Light Hydrocarbon and its vapour, Petrochemicals and its vapours.

- Corrosive Salt Solutions: Can handle corrosive salt solutions.

Materials Selection:

Metal Parts:

- SS316 (Stainless Steel),Alloy-20 (NickelChromium alloy),Hast-C (NickelChromium-Molybdenum alloy)

- Elastomers: Viton (FKM),Neoprene (CR),Silicon (VMQ),Aflas (TFE/P),EPDM (Ethylene Propylene Diene Monomer),NBR (Nitrile Butadiene Rubber),FFKM (Perfluoroelastomer),STV (Fluorosilicone).

Sealing Faces:

- Rotary Face:SiC (Silicon Carbide),Carbon Stationary Face:SiC (Silicon Carbide),TC (Tungsten Carbide),Ceramic.

Recommended Operating Conditions:

- Shaft Diameter: 25mm to 200mm

- Pressure: Maximum: Vacuum to 10 Bar

- Temperature: Maximum: Up to 200°C (dependent on elastomer selection),Note: Temperature range may vary based on the chosen elastomer material

- Speed: Maximum: 400 RPM